Cycle time for a 12-inch butterfly valve is approximately 39 seconds. The cycle time of Hayward’s HRSN2 electric actuator for a 4-inch ball valve is approximately 9 to 13 seconds.

Double acting air cylinder manual#

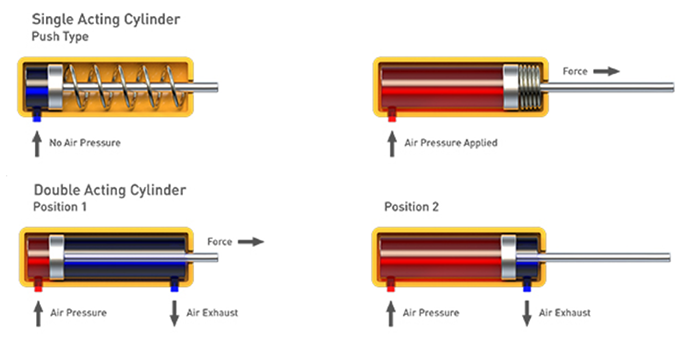

Options include solenoid (AC or DC), air filter/regulator, positioner (4-20 mA), auxiliary limit switches, visual indicator and declutchable manual override.Īctuator cycle time is the time it takes an actuator to travel from open to close and is important for preventing water hammer resulting from a valve opening or closing too fast. Pneumatic actuators require plant-supplied air and come as either double-acting or spring return. Valve operation: on/off, throttling (modulating 4-20 mA), 3-position.

Valve type: ball, butterfly, diaphragm, three-way ball.When considering actuating a thermoplastic valve, the following points need to be identified: It attaches to and works in conjunction with two parts: the valve body and the valve pilot. READ: Thermoplastic valves manufacturer, Asahi, acquires its Southern Africa distributorĪ valve actuator is the device that “actuates,” or moves, a valve open or closed. The same schedule 80 PVC ball valve will have a max pressure of 130 psi at 145☏. The pressure and temperature curves are different for PVC and CPVC.

Maximum operating pressure of a 2-inch ball valve can be 250 psi at 70☏, non-shock. EPDM rubber is an elastomer recommended for water, steam, dilute acids, dilute alkalis and alcohols.Īll thermoplastic material operating pressure decreases as temperature increases. When specifying a valve for a potentially corrosive application, consulting a chemical resistance chart for the thermoplastic and elastomer material chemical compatibility will ensure correct material selection. A thermoplastic butterfly valve also has a stainless steel or titanium shaft that holds the liner and disc assembly in place within the valve body. Thermoplastic butterfly valves have an elastomer liner that the disc seals into and O-rings made of EPDM, Viton or Nitrile. PTFE seats on either side of the ball provide a smooth travel and sealing surface for the ball to ride and seat against. These are located in the end connections and stem to create a sealing surface between plastic components. Incorrect material selection, especially of O-rings and liners, can lead to premature valve failure.īall valves use elastomer O-rings made of EPDM or FMP. All of these materials require careful attention during valve selection due to potential chemical compatibility. Thermoplastic valve assemblies additionally have smaller components made of different material that also interact with the liquid process. The thermoplastic valve body is precision moulded from the base material. Both materials inherently perform differently at the same operating temperature, pressure, impact and UV exposure. The most common materials used in thermoplastic valve manufacturing are PVC, CPVC, GFPP and PVDF. Thermoplastic valves fitted with electric or pneumatic actuators also allow for automated control and remote access by operators. Commonly used in municipal and industrial chemical feed systems, thermoplastic material is rugged and well-proven for industrial applications when used within the range of the material’s specifications. They also will not scale or rust and have low thermal conductivity. Thermoplastic valves have the advantage of being lightweight, corrosion resistant, chemical resistant and non-toxic.

0 kommentar(er)

0 kommentar(er)